Custom galvanized stainless steel stamping parts sheet metal welding processing and manufacturing

- group name

- CNC Part

- Min Order

- 1 piece

- brand name

- TZR

- Nearest port for product export

- ShenZhen

- Delivery clauses under the trade mode

- FOB, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, PayPal, Westem Union

- update time

- Fri, 25 Jan 2019 10:06:29 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Product description

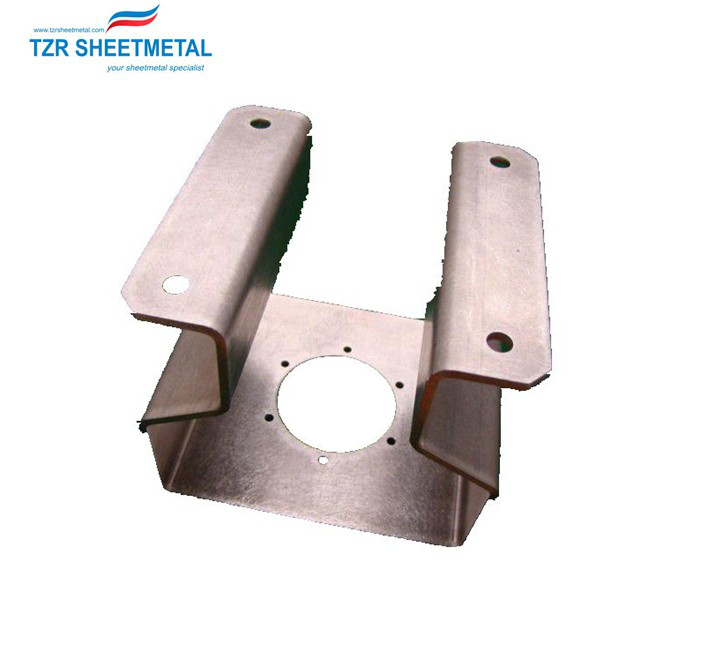

Item | Customized Structure Aluminum Galvanized Stainless Steel Stamping Parts Sheet Metal Welding Working Fabrication |

Material | Stainless steel 201/304/316, sheet metal ( SPCC, SECC), aluminum alloy etc. |

Surface treatment | Powder coating, Zinc plating, chrome plating, hot-dip, Silkscreen, polishing and so on. |

Thickness | 0.5mm-10mm |

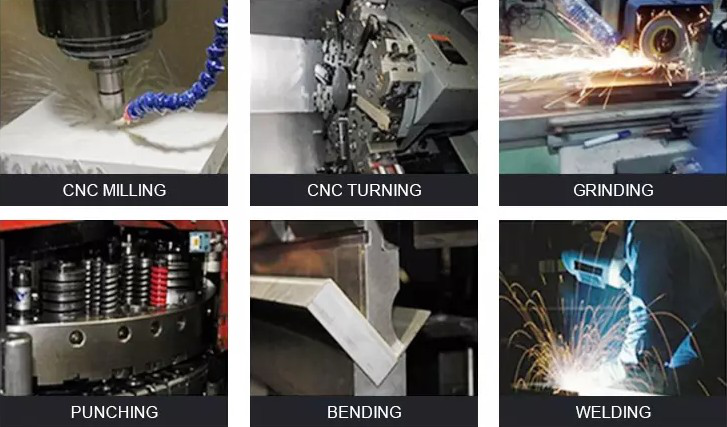

Process | Laser Cutting ,Stamping, Punching , Bending, turning ,Welding, machining, surface treatment, and other General Fabrication Service |

Design | ODM/OEM |

Color | As customer’s request |

Payment | T/T, Western Union, Paypal. 50% deposit before production, 50% balance payment before shipping |

Our products

Despite all the benefits of laser welding, including cost reduction in the long term, manufacturers are often discouraged by the initial investment costs. The LaserNetwork can drastically reduce this cost while increasing the laser source utilization by using a single laser for up to four machines. This lowers the entry barrier of implementing laser welding into production. Once the company has enough orders and high machine utilization, a second laser source can be retrofitted.

One of the keys to a successful implementation of laser welding is the part and fixture design. The part design must minimize gaps and avoid bending tolerances while the fixture has many requirements that can make its design very important. Not only must the fixture close gaps with force, it will consistently and precisely position the parts, be fast to load and unload, and enable good accessibility, while also functioning as a heat sink for the welding process. As a partner, TZR helps customers navigate these issues using its experience in lasers, sheetmetal design and welding processes. Laser welding is the next logical step and TZR has the know-how to support the implementation of this technology in your production process.

Product pictures

Process

Package & Shipping